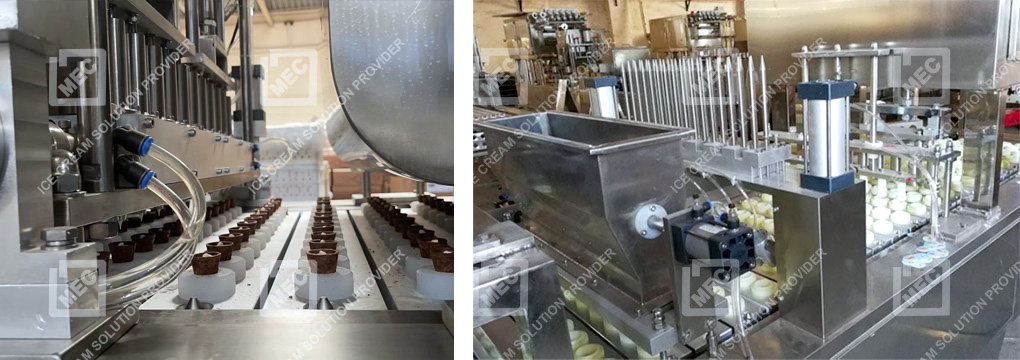

Bite-sized Chocolate Cone Filling Machine

Light and crunchy ice cream cones filled with smooth chocolate are becoming a popular snack in the market. These cones can be filled with anything you like, such as chocolate, jam or sauce, whole or chopped nuts, biscuits, etc. Every bite you take of the delicious cone will bring you enjoyment and pleasure. From sugar cone production, filling, cooling, sealing and packing, MEC offers robust and reliable automatic machines to produce the yummy cones.

Capacity: Our machine can produce 8, 10 or 12 lanes of cones at a time, with an output up to 10,000-11,000 pcs/h. (The specific output is depending on the cone size, the recipe and the filling content.)

| Packaging Type | Benefits |

|---|---|

|

Plastic cups

|

|

Paper sleeve

|

|

Film wrapping

|

Features:

Easy operation through state-of-the-art design

High product safety based on fully automated machine

Complete production line including cone feeding, filling and sealing

A necessity for large production line

Compliant hygienic design is secured by SS304 in the direct food contact, carbon steel in the inner frame and anti-aluminum mould (SS304 can also be applied to the inner frame through customization )

Linear motion lamella conveyors synchronously move with the main drive

Mitsubishi PLC for accurate control and easy changeover

Working Procedures of the machine:

1.Put the stacked sugar cone in the mould.

Both automatic and manual dispensing is applicable. The automatic dispensing is suitable for high-quality sugar cones.

2.Calibrate that the cone is aligned with the lamella.

3.Repetitively dose the cones with chocolate through the pressurized pumps. The chocolate filling device has the mixing unit, the hopper and the filling valve with a warming unit. Both single and double color fillings are available.

4.Cool down the paper sleeved or film wrapping cones with the cooling system. Water cooling or air cooling in a tunnel at a temperature of about -0-5°C (customizable) with a cooling time around 10 minutes. Refrigeration gas is R404A/R717 or other as requested by the customer.

5.Add granules through the dispenser.

The dispenser design varies according to the different solids content. Dispensing should be done with uniform-sized chopped nuts. Manual dispensation is suggested when adding whole nuts.

6.Transfer the finished product to the flow packer (manually).

Tel:

Tel: WhatsApp:

WhatsApp: Mail:

Mail: